Philosophy

Tiles as objects of possibility. Tiles that leave a sensory imprint. Tiles connecting future and past, design and craftsmanship, Japan and the world. Alternative Artefacts Danto is a dialogue between tiles and contemporary design. The new brand, also known as A.a. Danto, explores the possibilities of tiles as interior objects, pushing the boundaries of material, form and function.

It is the latest creative venture by Danto, one of Japan’s oldest mass producers of tiles, based since 1885 on the island of Awajishima in the Seto Inland Sea. A.a. Danto, creatively directed by Teruhiro Yanagihara Studio, aims to shift ideas behind the meaning of tiles and imagine a new interior paradigm.

The brand plans to collaborate with a range of international designers, architects and artists, in order to create tiles from a fresh, contemporary perspective. Collaborators can explore the layers of Danto’s heritage – its skilled craftsmanship, born from the tradition of Minpei-yaki ceramics; experimental soil compositions that provide a spectrum of clay shades; and flexible variations of form due to its mass production capabilities.

“A tile can completely shift the atmosphere of a space,” says Teruhiro Yanagihara. “Danto use natural materials that are fired, so have a similar feeling to ceramics. They’re soft, warm, crafted. We want to explore the potential for these tiles as an interior material.”

A.a. Danto will also breathe fresh life into Awajishima. Here, in its two factories, the tile journey unfolds – with signature soil innovations and experimental technical processes filtered through the vision of creatives from around the world.

History

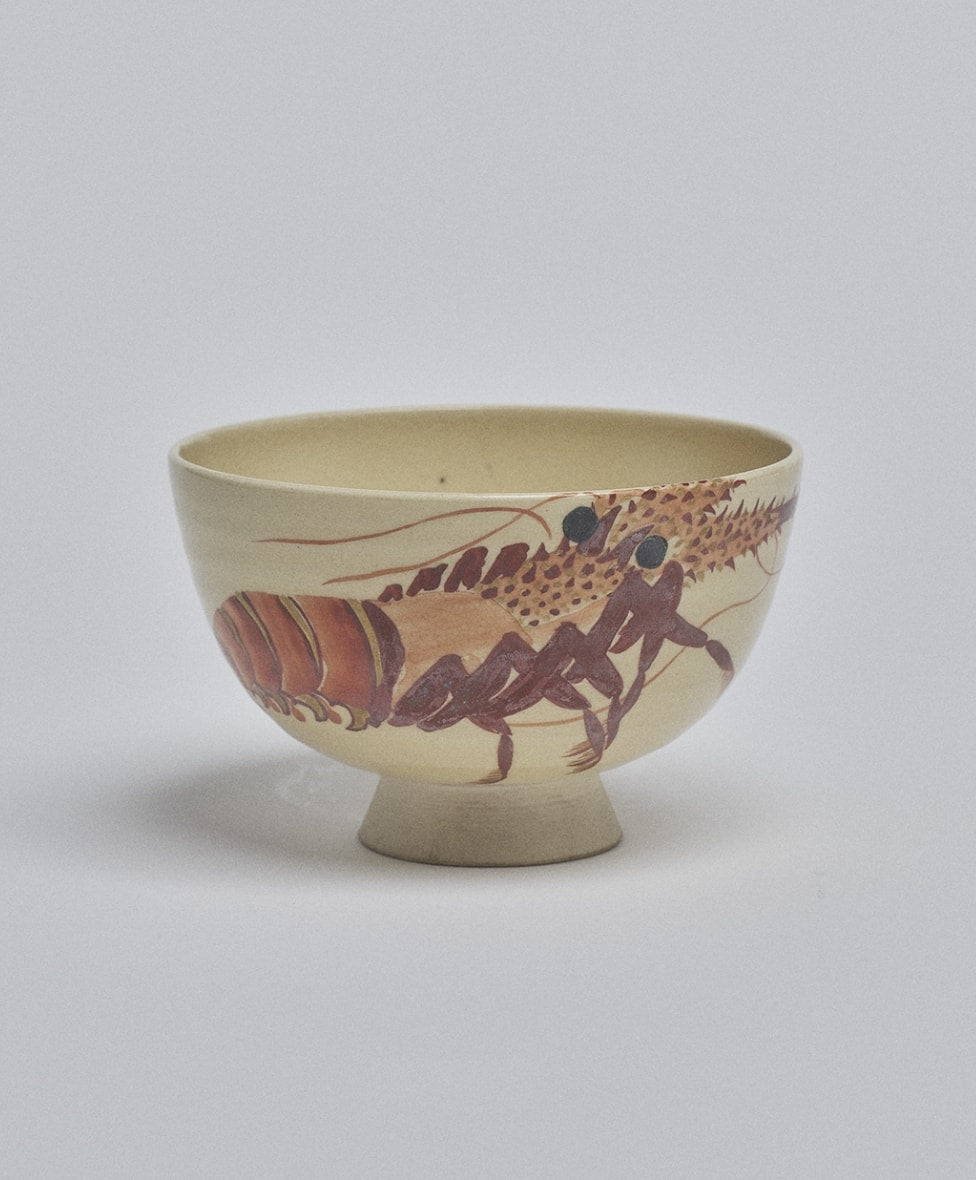

The story of Danto begins with a 19th century figure as colourful as its tiles: Minpei Kashu, an intellectual from Awajishima, who studied medical science, tea ceremony and the art of incense while running a soy sauce factory. His passion for pottery led him to create Minpei-yaki (or Awaji-ware), a ceramics style unique to Awajishima.

He opened the island’s first kiln in 1832 after studying under a famed Kyoto master. His works fused technical expertise with inspiration from China, Korea and Vietnam – resulting in an unusually modern style.

Typically using brilliant white Awajishima soil, early Minpei-yaki ceramics were highly regarded, due to moulds and vivid glazes in shades of yellow, red and green (admirers included the region’s powerful feudal leader).

In 1885, these kilns officially became Danto – a moment coinciding with the modernisation of Japan’s Meiji Era (1868-1912) and a rising wave of Japonisme sweeping the West.

Sensing the potential for innovation, Danto began experimenting – and made its first tile around 1890.

Danto debuted its tile making operation about ten years later, followed by full-scale production in 1908 – becoming one of Japan’s first mass producers of tiles.

Its tiles were highly sought after, fuelled by growing demand for European-style buildings after Tokyo’s 1923 earthquake. Danto was also known overseas for quality and versatility, due to designs, forms and glazes optimised for mass production.

Soil is key. Around early 1900, Danto switched from making extruded tiles with Awajishima soil to pressed tiles – created from a choreographed fusion of soils from across Japan (from Bizen and Shigaraki to Seto).

This formula is unique to Danto, just like its original mould and glazing techniques. This versatile raw material spans a spectrum of baseline tile shades, from light yellows and cloud greys to moss greens.

Danto’s innovations extend to design. From the start, its tiles intuitively distilled the shifting creative climate of a world beyond Japan. Early tiles fused Japanese motifs with Art Nouveau curves – while its 1970s surfaces reflected edgy fashion and design influences (collaborators included Bruno Munari).

The production of ceramics born from the Minpei-yaki movement ended around 1930, yet Danto’s tiles are still thriving.

Today, Danto continues to explore the boundaries of tiles, experimenting with technical and design innovations at two Awajishima factories , Fukura and Ama – the exact spot where it all began, with Kashu crafting his Minpei-yaki.

Techniques

Infinite. There is no end to the spectrum of possibilities for the tiles that Danto can bring to life, in colours, tones, textures, atmosphere.

The beauty of the tiles lies far deeper than surface level. This is because even on an industrial production scale, the entire process is rooted in a respect for the natural expression of the clay – from soil studies and material blending to moulding, glazing, firing and finishing.

The starting point is always the soil. Danto uses a unique process called seihai, which involves making clay from an array of raw materials from across Japan’s mountainous landscape (soil, feldspar, porcelain stone). These are collected and examined in a factory laboratory, to determine optimum blends depending on usage.

This exploratory approach fuels countless expressions of the natural material, through subtly shifting colour palettes and textures, without the need for glazes.

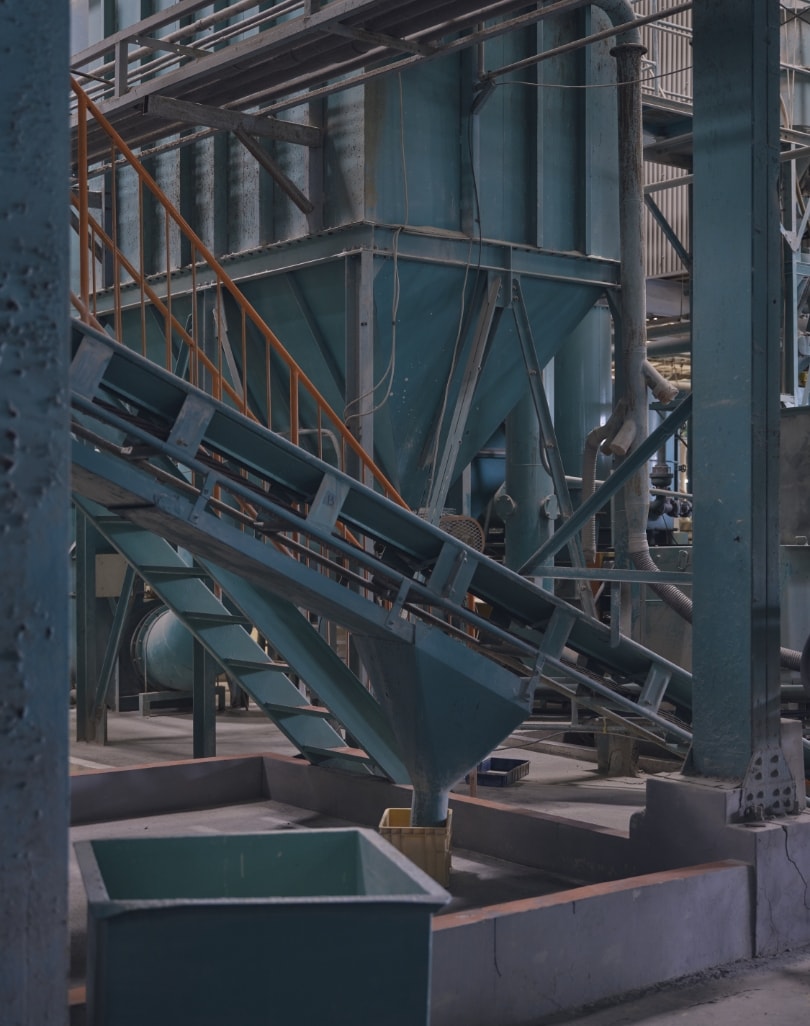

These soil blends are finely crushed into a slurry-like consistency, before being filtered and dehydrated, to create “cakes”: stackable discs of different soil formulations, spanning around 65 cm in diameter and 1.5 cm in height.

The cakes are pulverised into a powder with unusually large particles measuring 2-3mm, resulting in granite-like textural irregularities throughout the entire tile material.

As a result, Danto has the unique ability to simultaneously experiment with the creation of different clays, while developing and testing tiles being made from that same material.

By producing clay in-house, Danto is able to gain invaluable insights into the clay development process and apply them directly into its tile-making practices.

This journey of exploration and innovation would be impossible to achieve if the starting point was pre-made clay. Such creative experimentations with tiles on a mass production scale is a rarity in Japan.

The innovations continue with moulding. Square pieces of mould-pressed clay flow along a conveyor belt, with multiple layers successively overlaid onto their surfaces, resulting in a crafted depth in the final fired tile, despite the mass production scale.

For decorative elements, the surface level of the moulded clay is machine-sprayed, with a range of possible patterns, a technique that often results in subtle surface fluctuations softly reflecting the imperfections of the natural world.

Unlike the more common practice of surface-level tile printing, Danto embraces a soil-focused philosophy from start to finish, fuelling an unusual depth of atmosphere in the final product.

And threading together every step of the process? A timeless and open-minded passion for innovative experimentation – an approach that can be traced directly back to the spirit of Minpei-yaki ceramics, where it all began.

Profile

dan - Awajishima

to – pottery

Innovative. Experimental. Crafted. Open. Timeless. These are all qualities that underpin Danto – one of the oldest companies in Japan to mass-produce tiles.

Danto came to life in 1885 on the southern shores of Awajishima, a mountainous island steeped in nature and mythology, encircled by the blue waters of the Seto Inland Sea.

Its tiles are rooted in a richly layered history, threaded with innovative craftsmanship, experimental soil composition, glaze innovations, contemporary design and meticulous production.